step by step testing on water bottling|bottled water testing times : wholesaling Step 7: Raw Water Quality Testing for Mineral Water or Pure Water. . Building upon the previous steps of setting up your water bottling plant and recruiting staff, implementing a robust Inventory and Enterprise Resource Planning (ERP) system is crucial for efficient operations and accurate financial management. This step will focus on . Em comemoração do lançamento do “Youcine Premium” preparamos um MEGA sorteio para presentear nossos primeiros assinantes! E vocês vão amar os prêmios que escolhemos a dedo para vocês! Olha só: 10 .

{plog:ftitle_list}

WEBAssista vídeos pornô de Sarrando de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta qualidade. Nenhum outro site pornô é mais popular e tem mais cenas de Sarrando do que o Pornhub! Navegue pela nossa incrível seleção de de vídeos pornô em HD em qualquer dispositivo que você .

The first step is to determine what tests are appropriate to run at your plant. Depending on the source of your water (municipal, spring, artesian .

Step 7: Raw Water Quality Testing for Mineral Water or Pure Water. Step 8: Purchase & Install Equipment for Bottle Filling. Step 9: Recruit & Train Sta for Small Water Bottling Plant . end-to - end process to start a water bottling plan t: Step 1: Market Research & Feasibility Study of Drinking Water Market. Thoroughly research your target .

Adhering to regulations is crucial in the water bottling business in Kenya. Below are some of the key regulatory requirements: KEBS Certification: Bottled water must meet the standards set by KEBS (KS EAS 153:2015 for drinking water). This involves regular testing of water quality, labeling compliance, and inspections.Step 1: For in-state Bottled Water Manufacturers, contact the Michigan Department of Environment, Great Lakes, and Energy (), at 517-388-9818, for water source approval. Drinking Water & Environmental Health Division For in-state Bottled Water Manufacturers, EGLE will provide onsite inspection, if necessary, as well as evaluation of the water in question. Step 7: Raw Water Quality Testing for Mineral Water or Pure Water. . Building upon the previous steps of setting up your water bottling plant and recruiting staff, implementing a robust Inventory and Enterprise Resource Planning (ERP) system is crucial for efficient operations and accurate financial management. This step will focus on .

To launch a successful water bottle company, market research is fundamental. It will help you understand the demand, competition, and potential for growth in the market. Next, a business plan is crucial, detailing your company’s mission, target audience, marketing strategy, and financial forecast. Choosing the water bottle type and finding a supplier to meet your . Water bath processing steps. Put the food in the jars; Put the lids on; Have something on the bottom of the pot to be between the jars and the bottom of the pot; Put the jars upright in the water. Ensure the jars are covered by 3 to 5 cm (1 to 2 inches) of water. If not, add more water now. (Don’t be tempted to try to cheat and lay the jars . The best and most reliable way to test water for nitrates is by collecting and sending a water sample to a certified water testing lab. . How to Test Nitrates in Water (Step-By-Step) Written by Scott Winfield Last Updated on June 10, . Bottled Water Insights; Water Defense, 542 600 W, Provo, UT 84601 USA, (385) 314-3204 . Once all the components are securely in place, give your water bottle a test run. Fill it with water and make sure there are no leaks or loose connections. Customize your water bottle further by adding stickers, decals, or personalized labels. Let your creativity shine! Tools And Materials Needed. To assemble your water bottle, you’ll need .

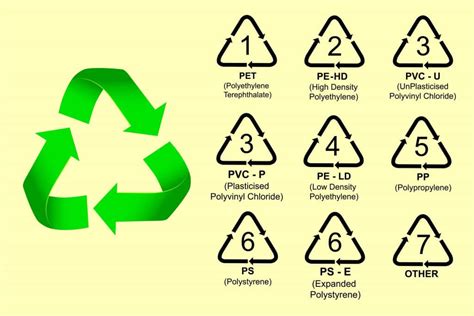

water bottle identification codes

Employing an extensive U.S.-patented 13-step purification process to obliterate all impurities, Penta Water is marketed as an ultra-pure, bottled water brand, completely free of nasty pollution . The bottled water industry is a lucrative market, valued at over 6.76 billion in 2023.As health trends shift towards sugar-free options and consumers place greater value on convenience, bottled water has become one of the fastest-growing beverage segments, with an expected 6.14% growth rate from 2023 to 2028. During on-site visit, they may pick up some sample of water for testing. Test reports of raw and processed water. Once you availed the BIS license, you are also need to obtain a report on raw as well as processed water from BIS. To serve such a purpose, you need to head over to LWTL (Local Water Testing Laboratory). . Step 7 – Bottle .

gallon of water testing

This simple water bath method of bottling (canning) tomatoes is a great way to preserve them for the months ahead. . Have a large bowl handy and a kettle for boiling water. Step 2 . Sorry for the late reply, but I’ve been away with very little wi-fi and no roaming! To test a seal on a Kilner jar, here’s what you do: To check the seal of . Pressure canning is unique from water bath canning in that it creates a high-pressure environment inside the canner which results in a higher boiling point of water. Under normal conditions, water boils at 212 degrees F. Add some pressure and the temps can reach as high as 250 degrees F! 5 lbs of pressure = 228 degrees F

The Centers for Disease Control and Prevention (CDC) recommends that well owners check for mechanical issues each spring and perform a water quality test at least once a year. Owners should also test well water quality under any of the following circumstances: A baby is expected in the home; The well has recently been affected by a floodWater bottles are made using different materials and techniques, depending on the type of bottle being produced. Here are the steps involved in the production of plastic water bottles. Step 1: Resin Production . The first step in making plastic water bottles is producing the resin.

Below are the steps to starting a bottled water business. Each step is linked to a specific section, allowing you to jump to your desired section or scroll to follow the steps in order. . Water Testing Kits: To consistently . Step-by-Step Process for Accurately Testing Your Pool Water. Each section below will cover the basics and walk through steps you can follow. I’ll also cover how to sample your water correctly and use your testing . Step 5: If you are using a cold-water steriliser, shake off any excess solution from the bottle and the teat, or rinse them with cooled boiled water from the kettle (not tap water). Step 6: Stand the bottle on the cleaned, disinfected surface. Step 7: Follow the manufacturer's instructions and pour the amount of water you need into the bottle .

Recap Of The Steps To Start A Water Bottle Manufacturing Plant Understanding The Demand And Potential Market. To start a successful water bottle manufacturing plant, it is essential to have a deep understanding of the demand and potential market. . Implement a robust quality control system, including testing samples, conducting audits, and . Learn the step-by-step process of bottling hot sauce, including choosing the right bottles, sanitizing and preparing them, filling, sealing, and labeling. . Start by washing the bottles thoroughly with warm soapy water. Use a bottle brush to clean hard-to-reach areas, such as the neck and bottom of the bottle. . and testing for shelf stability.Also make sure malo-lactic fermentation for appropriate wine is complete before bottling to avoid refermentation in the bottle. Sterile filtration is an option but involves equipment beyond the budget of most home winemakers. Preparing to Bottle. The first step in getting ready to put the finished product to sleep is preparing the bottles.

To use a digital water tester to test your water, follow these steps: Collect a sample of cold tap water in a clean container or cup; . switch to bottled water or boil your water (if microbiological contaminants are detected) to make it safe to drink. 📝 Interpreting Your Test Results. Once you have your test results, you can determine: So, let’s move ahead to the next step in manufacturing a water bottle: step 3: material selection. Step 3: Mold Making Exploring The Different Types Of Molds Used In Bottle Manufacturing. . Testing and modifications: Once the mold is created, it undergoes testing to check its functionality and performance. Any necessary modifications or . Water analysis is a vital process used to assess the quality and composition of water. It is a critical step to ensure that water is safe and clean for drinking, industrial use, agriculture, and aquatic ecosystems, just to name a few. . The Role Of Water Testing Laboratories. . such as a glass bottle or a plastic bag, to directly collect a .

who makes the best moisture meter

Cleaning physically removes dirt and germs, and Rathey says it’s this scrubbing process that’s the most important step for your water bottle. (Just like washing your hands is better than only .

Opening a water bottle company in India is a lucrative business opportunity given the growing demand for packaged drinking water. However, it requires thorough planning and adherence to various regulatory norms. Missteps can lead to legal complications and business failure. Hence, it is crucial to follow. 10 Steps to Open a Water Bottle Company .FDA, which regulates the bottled water industry as a packaged food product, may collect samples for testing from any bottled water facility at any time, whether for cause or during a routine inspection. However, as is the case with public water systems and the U.S. Environmental Protection Agency (EPA), which regulates public water systems (tap .

bottled water testing times

Os melhores jogos de slots online no CacaNiqueisOnline.co.

step by step testing on water bottling|bottled water testing times